Advantage

Advantage

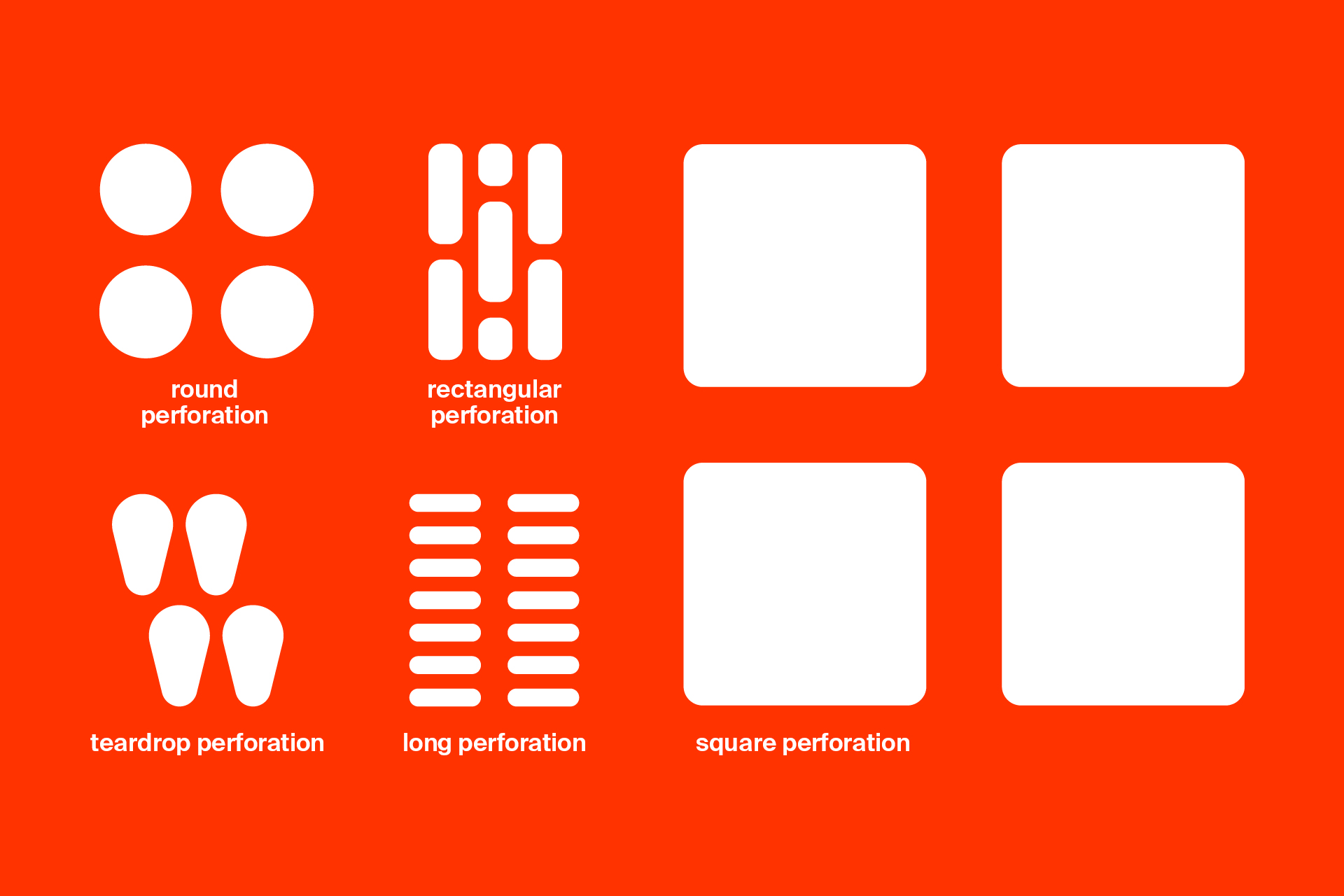

Variety provided by 5 types of perforation

Advantage

Advantage

Suitable for all C-pipe profiles

Advantage

Advantage

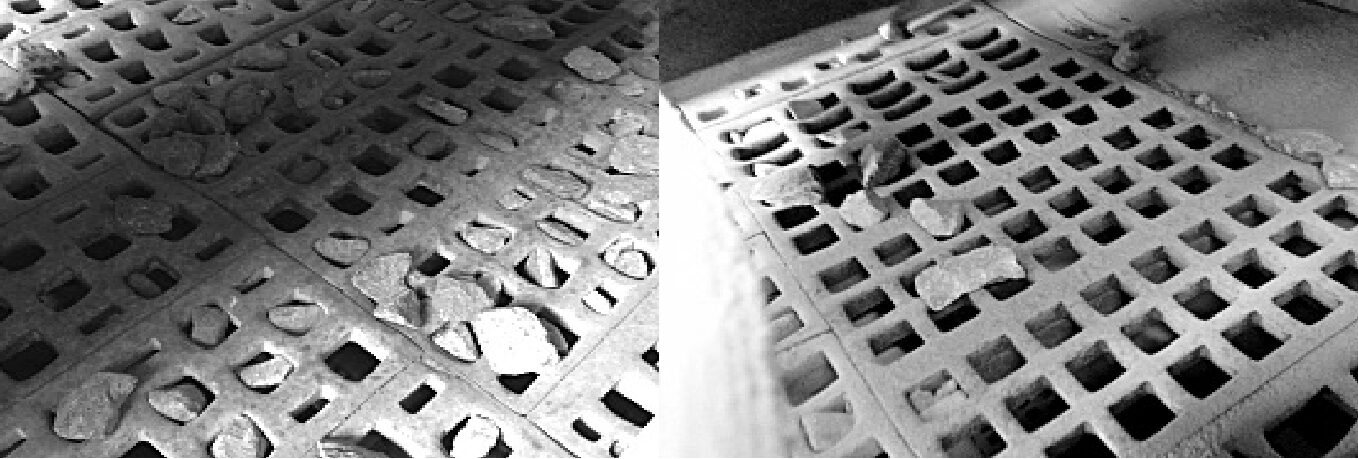

Blockages prevented by tapered holes

The perforation of hot vulcanised rubber screen panels opens in the direction of flow and there is far less chance of blockages forming than with the spherical perforation of stamped screen panels. The perforation is also less likely to tear on the sharp-edged screen material.

Materials

GIGANT

Vulcanised rubber with a hardness of approx. 60 Shore A. Very resistant to abrasion and elastic.

KÜPRENE

Wear-resistant polyurethane with a hardness of 90 Shore A. Elastic and impact-resistant. Resistant to water and many chemicals.

CLEAN

Vulcanised rubber with a hardness of approx. 35 Shore A. Extremely flexible and wear-resistant.

GK-SOFT

Polyurethane in various degrees of hardness up to 85 Shore A. Wear-resistant and elastic.

WIRE

Wear-resistant wire mesh, braided screens or pressure welded mesh in plug screen design.

Areas of application/Applications

Special properties

Plug screen panels made from rubber and polyurethane with conical perforation

Technology

Can be used on all standard C-pipes

Available in more than 100 different types of perforation

Product advantages

Simple to assemble and disassemble