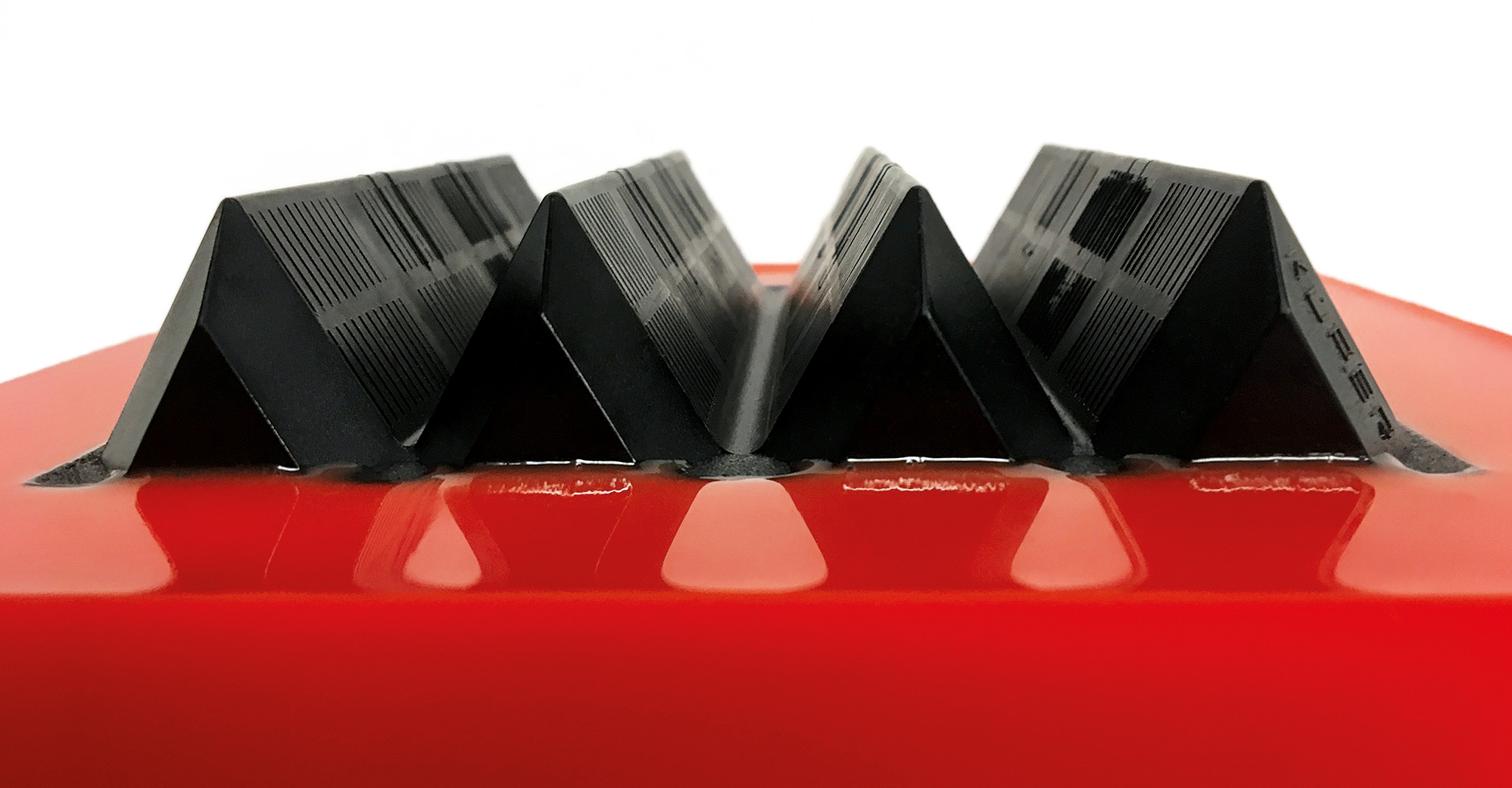

The clever arrangement of the mesh panels in prism rows maximises the open screen area, resulting in less surface water in the material and therefore considerably better drying. For greater efficiency during wet processing.

Dewatering screen panels

Extremely durable materials: custom-fit for a variety of applications.

Advantage

Advantage

Prism field SP 90: larger screen area for optimal drying

Advantage

Advantage

More efficient

Compared to the S 90 screen panel with a perforation of 0.5 x 16 mm and resulting screen area of 7.17%, the SP 90 prism screen field has an open screen area that is 139% larger, despite its smaller perforation of 0.5 x 10 mm.

+139%

This more than doubles the dewatering capacity (larger open screen area) compared to a standard dewatering field.

Advantage

Advantage

Blockage-free

The material in the prism field travels in channels. The screening material is torn open and no mass of material forms.

The perforation of hot vulcanised rubber screen panels opens in the direction of flow and there is far less chance of blockages forming than with the spherical perforation of stamped screen panels. The perforation is also less likely to tear on the sharp-edged screen material.

Advantage

Advantage

Available in all screening systems

Advantage

Advantage

Various types of perforation possible

The mesh panels are marked according to colour

0.15 mm = red

0.25 mm= grey

0.50 mm = black

0.75 mm = green

1.0 mm = white

Perforations are also possible in an open casting process (from 0.5 x 11/25 mm). They are cast into shape without pressure.

Perforation 0.75 x 16 mm

Areas of application/Applications

Special properties

Available as plug screens, flat screens and tensioned screens

Highly wear-resistant

Self-cleaning

Maximum screening performance

Technology

Available in GK-Soft and KÜPRENE

Product advantages

Extremely resilient and robust

No modification of the substructure

From fine-mesh dewatering screen panels to heavy rubber panels

For clearing and dewatering on vibration machines