KÜPER flat screen panels cover a wide range of applications.

From plastic dewatering panels with a gap width of just 0.16 mm to the Gigant panels for heavy-duty tasks, such as primary screening with a perforation diameter of up to 200 mm.

Flat screen panels

Extremely durable materials: custom-fit for a variety of applications.

Advantage

Advantage

Suitable for a variety of applications

Flat screen panels made from the sturdy GIGANT rubber

Use of TYPE B flat screen panels during dry processing in Poland

Advantage

Advantage

Lower noise emissions

KÜPER flat screen panels made from rubber or polyurethane reduce noise levels by almost 80% when compared to steel products.

–78%

Advantage

Advantage

Extremely durable

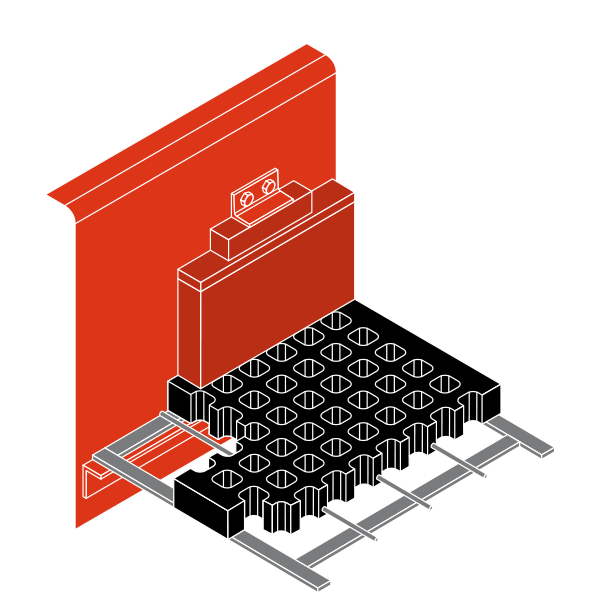

Type B flat screen panels with perforated plate are ideal for heavy-duty primary screening. Also possible as a self-supporting construction.

Advantage

Advantage

Sturdy construction

TYPE A flat screen panels have an integrated steel reinforcement, generally in the form of a frame construction.

Advantage

Advantage

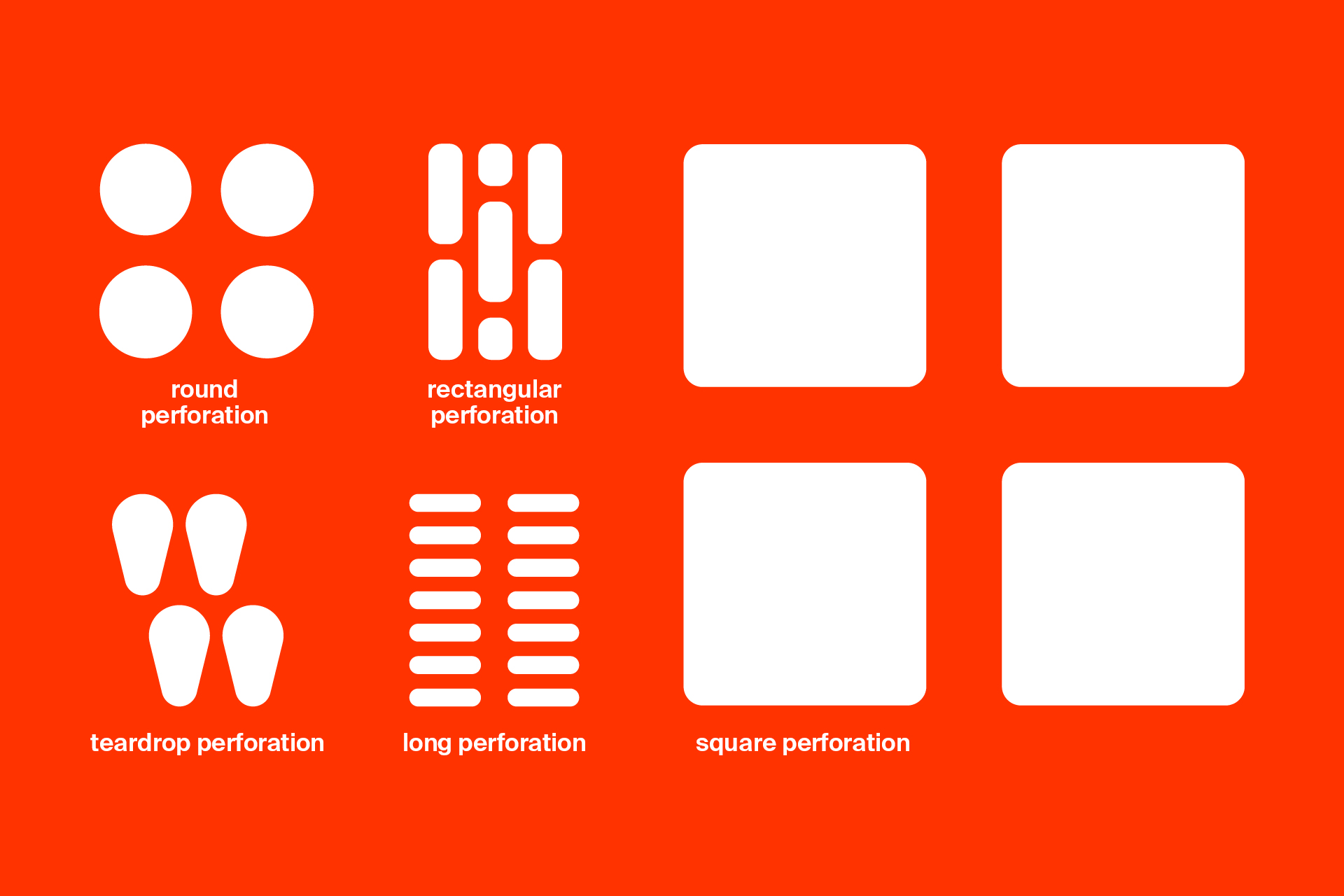

Variety provided by 5 types of perforation

Type A screen panel

Here, made from Gigant rubber with steel frame reinforcement and spring steel reinforcement in wedge form.

Type B screen panel

For example, as a self-supporting perforated plate construction with vulcanised rubber wearing surface and secured with a fixing plate.

Type P screen panel

For example, as a plastic flat screen panel reinforced in one direction with spring rods.

Areas of application/Applications

Special properties

Variety of designs and dimensions, also available as self-supporting flat screen panel

Technology

Available in all KÜPER materials

Product advantages

Extremely resilient and robust

No modification of the substructure

From fine-mesh dewatering screen panels to heavy rubber panels